Ball Valves

Ball Valves Specification

- Inlet/Outlet

- Threaded, Flanged, Socket Weld

- Caliber

- inch to 8 inch

- Working Temperature

- Up to 180C

- Mounting Type

- Horizontal, Vertical

- Control System

- Manual, Pneumatic, Electric Actuator

- Material

- Stainless Steel, Brass, Cast Iron, PVC

- Standard

- ISO 9001, ANSI, DIN, BS

- Pressure

- Up to 1000 PSI

- Usage

- Water, Oil, Gas, Industrial and Domestic Applications

- Application

- Water System, Chemical Industry, Food Industry, HVAC

- Seals Type

- PTFE, NBR, EPDM, or Custom

- Media

- Water, Oil, Gas, Chemicals, Steam

- End Connection

- Screwed, Flanged, Socket Weld, Butt Weld

- Seat Material

- PTFE, Reinforced PTFE

- Handle Type

- Lever or Gear Operated

- Operation

- Quarter Turn

Ball Valves Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Delivery Time

- 8 Week

- Main Export Market(s)

- Western Europe, Africa, Eastern Europe

- Main Domestic Market

- All India

About Ball Valves

We are offering one of best and quality tested Ball Valves to our valuable clients. This product is precisely designed and manufactured by knowledgeable professionals in exact accordance with the market requirements. The product has higher stability and reliability. This product is tested to ensure its flawlessness. Furthermore, clients can avail these Ball Valves in various dimensions, standards and grades as per their specific requirements at nominal rates.

Features:

- Easy installation

- High mechanical strength

- Impact resistant

Our clients can avail from us Ball Valves that is manufactured using superior quality raw material. These valves are widely appreciated by our clients for superior quality and optimum performance. Further, to earn total client satisfaction, we also offer customization facilities at highly affordable prices.

Versatile Design for Diverse Applications

Our ball valves are engineered to serve a multitude of industrial and domestic applications. Whether installed in water systems, chemical processing plants, food factories, or HVAC systems, their sturdy construction and varied mounting options (horizontal or vertical) ensure adaptability and dependable function. Choose from a wide selection of sealsincluding PTFE, NBR, EPDM, or custom solutionsto meet unique operational demands.

High Performance and Durability

These valves are built to withstand tough conditions, making them ideal for handling an array of media such as water, oil, gas, chemicals, and steam. With reinforced PTFE seats and advanced sealing technologies, they provide leak-free operation at pressures up to 1000 PSI and temperatures up to 180C. Manufactured from high-quality stainless steel, brass, cast iron, or PVC, they promise long service life and minimal maintenance.

FAQs of Ball Valves:

Q: How should I choose the right ball valve for my application?

A: Selecting the appropriate ball valve depends on several factors, including the type of media (water, oil, gas, chemicals, or steam), operating temperature, pressure requirements, and connection type (threaded, flanged, socket weld). Review the specifications such as seat material, seal type, and required mounting orientation to ensure compatibility with your system.Q: What are the main benefits of using PTFE and reinforced PTFE seats in these ball valves?

A: PTFE and reinforced PTFE seats offer excellent chemical resistance, low friction, and durability, making them suitable for a broad range of media, including aggressive chemicals and steam. Their low maintenance and ability to maintain tight seals at high temperatures and pressures add significant value in demanding environments.Q: When is it recommended to use a gear operated handle instead of a lever?

A: Gear operated handles are recommended for larger valve sizes (typically above 4 inches) or high-pressure applications up to 1000 PSI. They provide greater mechanical advantage, making it easier to open and close the valve smoothly and precisely, especially when manual force is insufficient.Q: Where can these ball valves be installed and operated?

A: These ball valves can be installed in both horizontal and vertical pipeline orientations across industrial sitesincluding water treatment plants, chemical factories, food manufacturing, and HVAC systemsas well as in domestic settings. Their robust construction and variety of control options (manual, pneumatic, electric actuator) support flexible installation and operation.Q: What is the typical process for installing and operating these ball valves?

A: Begin by verifying compatibility with the piping system and media. Install the valve using the correct end connection (screwed, flanged, socket weld, or butt weld), ensuring proper alignment. Operation is achieved via quarter turn of the handle, actuator, or gear operator, allowing for swift flow control. Routine inspection and maintenance are recommended to ensure optimal performance.Q: Can these valves be customized for specific industry standards or operational requirements?

A: Yes, our ball valves are available in configurations that comply with international standards such as ISO 9001, ANSI, DIN, and BS. Customization options for seals and body materials are also available to accommodate unique industry needs, such as food grade or chemical-resistant requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lubricant Equipments Category

Diesel Pump Nozzle

Minimum Order Quantity : 1 Unit

Standard : ISO 9001:2015

Usage : Other, Diesel Transfer

Noise Level : <70 dB

Discharge Pressure : 0.3 MPa

Material : Aluminum Alloy

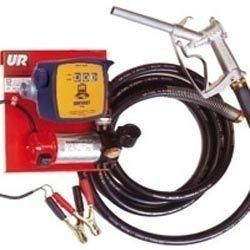

Diesel Pump Meter

Minimum Order Quantity : 1 Unit

Standard : ISO9001

Usage : Other, Industrial/Commercial Diesel Transfer

Noise Level : 80 dB

Discharge Pressure : 0.28 MPa

Material : Aluminum Alloy

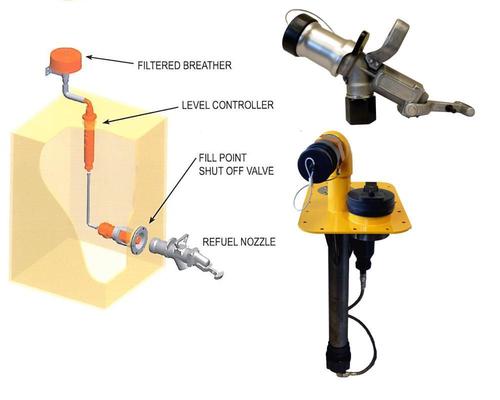

Pressure Less High Flow Refuelling System

Minimum Order Quantity : 1 Unit

Standard : ISO 9001:2015

Usage : Other, Bulk fuel transfer and refuelling

Noise Level : <85 dB(A)

Discharge Pressure : Less than 1 bar

Material : Aluminum alloy and stainless steel

Grease Feeders

Minimum Order Quantity : 1 Unit

Standard : DIN, ISO compatible threads

Usage : Other, Bearings, chains, slideways, small machinery

Noise Level : Silent operation

Discharge Pressure : Up to 6 bar

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS